Foam manufacturers make polyurethane foam by reacting polyols and diisocyanates, both products derived from crude oil. A series of additives are necessary to produce high-quality PU foam products, depending on the application the foam will be used for.

Polyurethane foam is widely used in high resiliency flexible foam seating, rigid foam insulation panels, microcellular foam seals and gaskets, durable elastomeric wheels and tires, automotive suspension bushings, electrical potting compounds, seals, gaskets, carpet underlay, and hard plastic parts (such as for electronic instruments).

List of polyurethane applications

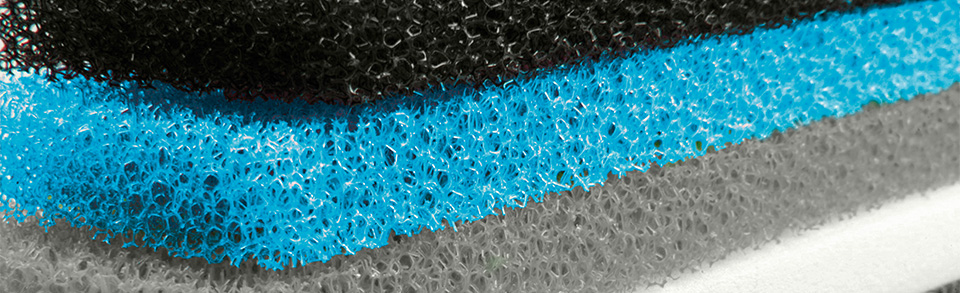

Polyurethane formulations cover an extremely wide range of stiffness, hardness, and densities. These materials include:

- Low-density flexible foam used in upholstery, bedding, automotive and truck seating, and novel inorganic plant substrates for roof or wall gardens.

- Low density elastomers used in footwear.

- Hard solid plastics used as electronic instrument bezels and structural parts.

- Flexible plastics used as straps and bands.

- Cast and injection molded components for various markets — i.e., agriculture, military, automotive, industrial, etc.

how to make polyurethane foam

While polyurethane polymers are used for a vast array of applications, their production method can be broken into three distinct phases. First, the bulk polymer product is made.

Next, the polymer is exposed to various processing steps. Finally, the polymer is transformed into its final product and shipped.

This production process can be illustrated by looking at the continuous production of polyurethane foams.

Polymer reactions

- At the start of polyurethane foam production, the reacting raw materials are held as liquids in large, stainless steel tanks. These tanks are equipped with agitators to keep the materials fluid. A metering device is attached to the tanks so that the appropriate amount of reactive material can be pumped out. A typical ratio of polyol to diisocyanate is 1:2. Since the ratio of the component materials produces polymers with varying characteristics, it is strictly controlled.

- The reacting materials are passed through a heat exchanger as they are pumped into pipes. The exchanger adjusts the temperature to the reactive level. Inside the pipes, the polymerization reaction occurs. By the time the polymerizing liquid gets to the end of the pipe, the polyurethane is already formed. On one end of the pipe is a dispensing head for the polymer.

Processing

- The dispensing head is hooked up to the processing line. For the production of rigid polyurethane foam insulation, a roll of baking paper is spooled at the start of the processing line. This paper is moved along a conveyor and brought under the dispensing head.

- As the paper passes under, polyurethane is blown onto it. As the polymer is dispensed, it is mixed with carbon dioxide which causes it to expand. It continues to rise as it moves along the conveyor. (The sheet of polyurethane is known as a bun because it “rises” like dough.)

- After the expansion reaction begins, a second top layer of paper is rolled on. Additionally, side papers may also be rolled into the process. Each layer of paper contains the polyurethane foam giving it shape. The rigid foam is passed through a series of panels that control the width and height of the foam bun. As they travel through this section of the production line, they are typically dried.

- At the end of the production line, the foam insulation is cut with an automatic saw to the desired length. The foam bun is then conveyored to the final processing steps that include packaging, stacking, and shipping.